E-mail

E-mail

Return to Main Dragonfly Page

Return to Dave's Main Page

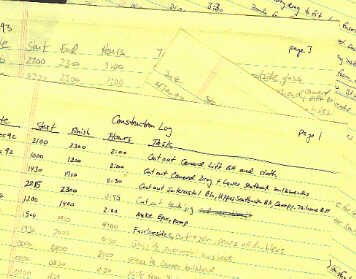

| Date | Duration Hrs:Min | Task Performed *Abbreviations below |

|---|---|---|

| 20Dec | Received plans as an early Xmas present Wife and kids go on trip! | |

| 21Dec | 8:00 | Read plans; Read all back-issues of Newsletter; Cut out errata notes and tape into plans |

| 23Dec | 2:00 | Cut out canard lift bulkhead foam and cloth |

| 24Dec | 2:00 | Cut out canard drag & lower seatback bulkhead foam |

| 24Dec | 2:30 | Cut out intercostal BH, upper seatback BH, canopy BH, tailcone BH |

| 24Dec | 0:45 | Cut out tank jig |

| 28Dec | 2:00 | Build epoxy measuring scale |

| 30Dec | 4:00 | Cut out and join fuselage sides, cut out all doublers |

| 30Dec | 0:30 | Glass 1/2 intercostal BH |

| 31Dec | 2:00 | Glass canopy BH |

| 31Dec | 0:30 | Knife trim intercostal BH and canopy BH |

| 31Dec | 2:00 | Lay out fuselage & mark RH inside |

| 31Dec | 1:00 | Cut fuselage & synchronize with LH side; Sand & trim |

| 31Dec | 2:00 | Install & shape doublers on RH inside |

| 31Dec | 1:00 | Glue in doublers on RH inside |

| 31Dec | 2:00 | Install & shape doublers on LH inside; Glue fwd doubler |

| 31Dec | 2:00 | Prep canopy BH; Glass 2nd side |

| 01Jan | 0:30 | Knife trim canopy BH |

| 01Jan | 1:30 | Attach doublers LH side fuselage; Layout fuselage bottom |

| 01Jan | 2:30 | Cut out bottom & glue together & add doublers |

| 01Jan | 1:30 | Glue in LH doublers |

| 01Jan | 5:00 | Build fuel tank |

| 02Jan | 3:00 | Knife trim tank; Fit fuselage sides; Locate tank & BH |

| 02Jan | 1:00 | Prep fuselage bottom for glass; Add tail doubler to bottom |

| 02Jan | 5:30 | Cut bottom cloth; Glass fuselage bottom |

| 03Jan | 0:15 | Knife trim edges of fuselage bottom |

| 03Jan | 3:00 | Cut glass for upper & lower seatback BH, canard drag BH; Fix intercostal BH; Cut out fuel tank baffles & cloth |

| 03Jan | 2:30 | Glass 4 above BH; Glass tank baffles; Glass repaired intercostal BH; Make tank filler tube |

| 04Jan | 6:00 | Cut glass, shape for glass/glass bond and glass: intercostal, tailcone, upper & lower seatback BH |

| 04Jan | 1:00 | Knife trim all above |

| 05Jan | 1:00 | More knife trim |

| 07Jan | 3:00 | Glue and Glass fuel tank baffles into position in tank |

| 08Jan | 4:00 | Trim fuel tank, fuselage bottom; Trial assembly; Fit upper & lower seatback B& around doublers; Fit fuel tank |

| 10Jan | 1:00 | Cut out wing lift and drag BH |

| 11Jan | 1:00 | Cut out 12 plywood inserts and glue together |

| 13Jan | 1:00 | Trim plywood inserts & glue into bulkheads |

| 14Jan | 2:00 | Repair tail delamination; Move air vent hole to correct location |

| 15Jan | 2:00 | Set up longerons for lamination, glue them together, put fuselage away |

| 16Jan | 4:00 | Split longerons; Dress to 3/4" x 3/4"; Glue to fuselage sides |

| 16Jan | 0:30 | Change lower stringers to correct angle |

| 16Jan | 1:30 | Patch RH fuselage side holes; Glue on tail doubler |

| 17Jan | 3:00 | Cut out 5 layers of glass for RH fuselage inside |

| 17Jan | 3:30 | Glass RH fuselage inside |

| 18Jan | 0:30 | Knife trim |

| 23Jan | 1:00 | Build 2 sawhorses with wheels |

| 23Jan | 1:30 | Cut out 5 layers of glass for LH fuselage inside |

| 24Jan | 3:00 | Glass LH fuselage inside |

| 24Jan | 0:30 | Knife trim |

| 30Jan | 1:30 | Cut glass: wing drag BH, canard lift BH; Glass front sides of those |

| 30Jan | 2:00 | Trim BHs; Glass front of wing lift BH |

| 31Jan | 2:00 | Cut out firewall; Knife trim wing lift BH; Cut out firewall elbows |

| 31Jan | 1:00 | Cut glass for fuel tank outside and 3 bulkheads |

| 31Jan | 2:30 | Glass fuel tank outside; Glass 2 bulkheads |

| 01Feb | 1:00 | Trim & sand fuel tank outside glass |

| 02Feb | 1:00 | Trim fuel tank, wing lift BH, canard lift BH |

| 04Feb | 1:00 | Cut fuel filler hole, trim edges, cut tube holes |

| 06Feb | 1:00 | Fabricate drain plug plate & tap hole |

| 06Feb | 1:00 | Glue drain plug plate into fuselage bottom; Sand |

| 06Feb | 2:00 | Install fuel filler neck; Flox canard lift BH |

| 07Feb | 1:00 | Smooth & sand inside of fuel tank |

| 08Feb | 1:00 | Shape canard drag corners to fit fuselage sides |

| 27Feb | 1:15 | Cut & shape fuel tank tubing; Install & glass filler tube to tank |

| 27Mar | 1:00 | Glass 2nd side wing drag BH |

| 28Mar | 2:00 | Install fuel tank in fuselage bottom |

| 29Mar | 1:00 | Install fuel strainer |

| 29Mar | 2:00 | Bondo in BHs to fuselage bottom for trial fitting |

| 30Mar | 1:30 | Fit fuselage sides to BHs |

| 31Mar | 1:30 | Bondo in bottoms of intercostal BH, tailcone, wing lift to fuselage bottom |

| 03Apr | 4:00 | Tape seatback BH, intercostal BH, wing lift & drag BH, tailcone BH, front & rear of tank to fuselage bottom |

| 04Apr | 0:30 | Knife trim, make adjustments |

| 06Apr | 1:00 | Trim BH more for left fuselage side fit |

| 11Apr | 2:45 | Flox RH fuselage side to bottom |

| 16Apr | 2:00 | Flox tank to RH side; Flox RH to fuselage bottom; Tape rear RH to fuselage bottom |

| 05Sep | 0:30 | Study plans; Sweep cobwebs out of interior; Do some sanding of flox corners |

| 09Sep | 1:00 | Tape fuselage side to tank and seatback bottom |

| 12Oct | 0:30 | Cut out tapes for RH-to-bottom fuselage |

| 23Oct | 1:00 | Tape LH seatback, RH fuselage side, wing lift BH to fuselage bottom |

| 25Oct | 2:00 | Mate LH fuselage side to bottom |

| 03Nov | 0:45 | Fit firewall to fuselage sides; Trim longeron holes |

| 12Nov | 0:30 | Trim wing drag BH to fit LH fuselage side |

| 11Dec | 0:30 | Bondo one half of rear turtledeck foam into mold |

| 12Dec | 3:30 | Re-do above (didn't hold); Use string instead of Bondo; Do second half of foam also; Trim; Scab on filler pieces |

| 13Dec | 2:00 | Cut fiberglass for rear turtledeck; Trim foam; Build new epoxy scale |

| 26Feb | 2:00 | Glass inside rear turtledeck (first use of PH3660 - good stuff!) |

| 27Feb | 1:30 | Cut rear turtledeck out of mold; Trim threads off |

| 27Feb | 0:30 | Sew one half of forward turtledeck foam into mold |

| 01Mar | 1:00 | Sew second half of forward turtledeck foam into mold |

| 03Mar | 2:00 | Glass forward turtledeck inside |

| 05Mar | 1:00 | Trim edges; Fit fwd turtledeck to fuselage; Repair missing chunks |

| 06Mar | 1:00 | More prep of LH fuselage side to bottom joints for later glassing |

| 20Mar | 1:30 | Glass LH fuselage side to bottom and tank front, wing, tail |

| 22Mar | 1:00 | Scab foam onto fuel tank to LH fuselage side joint |

| 01May | 1:30 | Glass LH fuselage side to bottom at tank & lower seatback BH |

| 04May | 2:00 | Extend side edges of rear turtledeck to raise it; Add 1" extension to upper seatback BH |

| 22May | 0:45 | Seal inside of tank with flox; Flox lower seatback to wing lift BH |

| 05Jul | Got divorced | |

| 03Sep | Ottawa fly-in | |

| 02Oct | 0:30 | Bondo wing lift BH and wing drag BH to LH fuselage side |

| 08Oct | 1:30 | Glass LH fuselage side to lower seatback BH and fuselage bottom remainder |

| 18Feb | 1:30 | Build gear leg mold for hoop style gear |

| 19Feb | 1:30 | Start over and make new gear leg mold |

| 02Sep | Ottawa fly-in | |

| 03Sep | 0:30 | Shape styrofoam in gear mold |

| 04Sep | 2:15 | More work on gear mold |

| 09Sep | 2:30 | Layup about half of the gear leg UNI tape fiberglass into mold |

| 16Sep | 3:30 | Add more layers of UNI tape glass to gear |

| 17Sep | 2:00 | Finish glassing UNI tape layers of gear |

| 23Sep | 1:00 | Sand gear leg and prep for outer skin |

| 27Sep | 0:30 | Attach brake line to gear leg |

| 29Sep | 1:30 | Build foam fairing for RH brake line; Cut foam; Attach foam to gear RH side |

| 30Sep | 1:30 | Build foam fairing for LH brake line; Cut foam; Attach foam to gear LH side |

| 01Oct | 1:30 | Cut glass for gear bottom skin; Layup 3 layers |

| 02Oct | 0:30 | Knife trim |

| 04Oct | 1:00 | Sand gear leg; Shape fairings; Prep for top glass skin |

| 11Oct | 0:45 | Glass top of RH side gear leg |

| 18Oct | 1:00 | Inject micro into gaps in gear skin RH side |

| 23Oct | 1:00 | Shape leading edge of gear with micro |

| 24Oct | 0:45 | Glass top of LH side gear leg |

| Oct | Lay hardwood floor in livingroom; Re-carpet bedroom; Re-paint entire house | |

| 01Sep | Ottawa fly-in | |

| 07Sep | 1:00 | Fabricate aluminum angle brackets for gear attach points inside fuselage |

| 30Aug | Ottawa fly-in | |

| 11Sep | 1:00 | Cut out 7 console (armrest) foam pieces and trial fit to fuselage |

| 11Sep | 0:30 | Cut out instrument panel foam |

| 13Sep | 1:00 | Fill all gouges in fwd and rear turtledeck with micro |

| 20Sep | 0:45 | Glass inside of LH and RH console parts |

| 20Sep | 0:30 | Cut high density foam and shape into tail |

| 20Sep | 0:30 | Glass inside of center console |

| 20Sep | 0:15 | Micro high density tail piece into fuselage bottom & sides |

| 21Sep | 0:30 | Glue together center console parts |

| 21Sep | 1:00 | Glue together LH and RH console parts |

| 21Sep | 2:00 | Shape & glass outside of consoles |

| 22Sep | 0:30 | Knife trim consoles |

| 11Oct | 6:00 | Cut out tail fin templates; Hot wire cut out tail (Kathleen assisting) |

| 12Oct | 1:30 | Re-cut trailing 1/2 of tail fin to fix problem of incorrect tube cutout in first attempt |

| 16Oct | 2:00 | Glass tail fin shear web |

| 19Oct | 2:00 | Tail foam inserts; Fin bottom fuselage insert; Contour shaping |

| 20Oct | 0:30 | Glass RH side tail fin carbon spar |

| 23Oct | 3:00 | Glass LH side carbon spar & skin LH side tail fin |

| 27Oct | 0:30 | Knife trim LH side tail fin |

| 05Nov | 1:00 | Cut glass for RH side tail fin skin; Prep core |

| 07Nov | 2:00 | Glass RH side tail fin |

| 07Nov | 0:30 | Try to cut rudder hinges with hacksaw; Give up |

| 15Nov | 1:15 | Glass RH side rudder |

| 16Nov | 0:30 | Knife trim; Cleanup; Trim RH rudder |

| 16Nov | 4:00 | Cut out all wing lift fittings and inserts, rudder hinges (using diamond cutting wheel) |

| 16Nov | 0:30 | Repair leading edge of rudder with flox and micro |

| 17Nov | 1:30 | Glass LH side rudder |

| 18Nov | 0:30 | Knife trim rudder; Fit to fin for hinges |

| 19Nov | 2:00 | Cut all holes in rudder hinges |

| 23Nov | 2:00 | Sand round trailing edge of fin; Glass-glass bond trailing edge |

| 23Nov | 1:00 | Knife trim, shape, smooth, sand |

| 29Nov | 2:00 | Fit tail fin to fuselage; Drill hole in tailcone BH for pitot tube; Cut out top rudder hinge access hole in rudder tube |

| 29Nov | 0:30 | Experiment with West 410 Microlight & Aeropoxy as filler on gear leg RH side |

| 30Nov | 0:30 | Sand RH gear leg filler |

| 30Nov | 1:00 | Fill in groves on RH gear leg filler; Filler RH rudder side w/410 & Aeropoxy |

| 02Dec | 0:45 | Sand RH rudder and LH gear leg |

| 06Dec | 0:15 | Fill in grooves in LH gear leg and RH rudder |

| 10Dec | 2:00 | Sand high density foam in tail; Glass the tail rod & embed into tail; Cover with glass layers |

| 11Dec | 0:15 | Knife trim tail rod |

| 12Dec | 1:15 | Split center console, remove 1/2", repair w/glass tape, flox, micro |

| 18Dec | 1:00 | Study plans re: rudder hinges |

| 21Dec | 1:30 | Install upper rudder hinge; Rivet in place; Cut upper slot into HD foam; Flox upper hinge arm into slot |

| 22Dec | 2:00 | Drill rudder horn reducer; Cut upper slot into HD foam; Flox lower hinge arm into slot |

| 27Dec | 2:30 | Trim lower rudder to fit tailspring; Epoxy 2 MS-21047-3 nuts onto wood block and epoxy block into rudder to match with AN3-10 bolts thru rudder horn arm |

| 28Dec | 2:00 | Make rudder cap from foam; Cut out plywood rudder cap rib; Shape foam, plywood, rudder into smooth piece; Epoxy 7oz lead shot into rudder cap; Glue cap onto plywood rib |

| 28Dec | 0:45 | Glass rudder cap onto rudder |

| 30Dec | 0:30 | Repair rudder cap delaminations and air pockets around plywood rib and leading edge |

| 01Jan | 0:30 | Cut out phenolic rudder bearing, drill 1/2" hole and attach to tailspring with 5 min epoxy |

| 04Jan | 1:30 | Add glass to 2 repair spots on rudder cap; Add flox corners and glass tail fin top; Glass side of tail fin cap with pitot angle tube installed |

| 08Jan | 1:30 | Glass remainder of tail fin cap top and bottom; Flox rudder bearing onto tailspring; Apply West 410 to tail fin LH side bottom portion with groved trowel; Fill in groves on upper portion |

| 11Jan | 2:00 | Fill in groves on LH tail fin lower portion with West 410; Sand upper portion smooth; Glass rear of tail fin cap |

| 14Jan | 1:00 | Sand and fill depressions in LH tail fin some more; Fill some more on RH rudder |

| 15Jan | 1:00 | Sand LH tail fin more; Sand RH rudder more |

| 18Jan | 1:00 | Sand LH tail; Trial fit tail on fuselage |

| 25Jan | 1:30 | Cut vertical bar out of upper seatback BH; Add carbon fiber around curved section; Add layer of cloth; Glass on 1" extension; Add layer of cloth & peel ply to center console top |

| 26Jan | 0:45 | Trowel 410 Microlite on tail RH and rudder LH |

| 22Mar | 1:45 | Sand tail RH & add filler to grooves; Trowel filler on remainder of rudder LH |

| 29Mar | 1:30 | Sand tail RH & fill pinholes and depressions; Sand rudder LH & add filler to grooves |

| 06May | 5 days | Drive to Camarillo and buy Nate Rambo's wing and canopy and some other odds and ends. Bring wing back strapped to roof of van |

| 18May | 2:00 | Trial fit Nate's wing to fuselage; Trim rear turtledeck wing cutouts to match wing contour |

| 24May | 1:00 | Fabricate CS-13 phenolic bearing |

| 25May | 1:00 | Re-fabricate CS-13 bearing (made first one too large); Fabricate CS-14 and CS-15 bearings and trial fit to bulkheads |

| 28May | 1:00 | Shape RH fuselage to bottom edge |

| 29May | 1:00 | Shape RH fuselage to bottom edge; Shape forward turtledeck to forward RH and LH fuselage |

| 30May | 2:00 | Finish shaping RH and LH fuselage bottom edge |

| 30May | 3:00 | Glass fuselage bottom |

| 30May | 0:15 | Knife trim |

| 31May | 1:00 | Cut forward turtledeck to match canopy; Remove old canopy hardware and trim forward cover to fit |

| 01Jun | 2:00 | Study plans and newsletters regarding instrument panel, forward bulkhead, canopy, transverse header tank |

| 02Jun | 2:00 | Cut forward cover to match canopy; Remove old canopy hardware |

| 03Jun | 1:00 | Glass aft face of forward bulkhead |

| 05Jun | 1:00 | Cut out and glass one face of canopy hinge arms with 2 plies 10oz |

| 07Jun | 0:30 | Glass other side of hinge arms with 2 plies 10oz + 1 ply each end + 1 ply on straight section |

| 20Jun | 1:30 | Flox edges of canopy hinge arms, wrap one hinge with 1 ply 6oz |

| 1:00 | Cut, shape, and micro 1 hat section stiffener in place | |

| 21Jun | 1:00 | Glass hat section stiffener in place; Wrap 2nd canopy hinge arm with 1 ply 6oz |

| 1:30 | Drill hole in rear console phenolic bearing to fit Azusa wheel bearing and 10min epoxy both phenolic bearings in place in center console; Knife trim 2nd canopy hinge arm | |

| 22Jun | 1:00 | Cut and drill forward aileron torque tube; Glass phenolic bearings in place in center console |

| 23Jun | 1:30 | Sand fiberglass off phenolic bearing faces around hole; Drill holes and install all tubing in console |

| 30Jun | 2:00 | Tear apart Thrustmaster joystick; Drill and cut 1/2" .035 4130 tube and assemble with joystick grip |

| 04Jul | 1:00 | Cut aluminum tubing for control stick inside clamp; Sand old tailwheel fiberglass stinger paint off |

| 1:30 | Glass upper seatback BH aft face using tapes, flox, foam | |

| 13Jul | 3:00 | Cut instrument panel holes; Cut legs off panel, shape and glass them |

| 15Jul | 1:00 | Glass fwd face of instrument panel & peel ply |

| 16Jul | 1:30 | Sand edges of Fwd BH, RH console; Tack RH console and RH/LH instrument panel legs to fuselage with 5 min epoxy |

| 1:30 | Tape-glass upper seatback BH fwd face; Flox and tape-glass RH console into place | |

| 21Jul | 2:00 | Adjust fit of Fwd turtledeck; Trim and glass it |

| 22Jul | 0:30 | Knife trim Fwd turtledeck; Sand interior of cockpit and eliminate snags |

| 2:30 | Fit Fwd BH to fuselage sides & Fwd cover; Trial-fit header tank to Fwd BH with screws | |

| 25Jul | 1:30 | Drill control stick outer tube and install completed stick in console |

| 3:00 | Cut out new roll bar foam (behind Seatback BH) and put on 1st layer of 10oz bid; Attach roll bar to Seatback BH | |

| 0:30 | Cut out and lay up 2nd layer 6oz on roll bar | |

| 26Jul | 1:00 | Trim aft fuselage cover to fit roll bar |

| 1:30 | Flox Fwd BH in place on RH side | |

| 1:15 | Cut canopy hinges to fit Fwd BH and place wood insert into one | |

| 2:00 | Glass canopy hinges to canopy with flox and 10oz and 6oz bid | |

| 27Jul | 0:30 | Knife trim hinges; Test placement on Fwd BH |

| 28Jul | 3:00 | Attach struts and glass Fwd BH to fuselage side with 2 layers 10oz |

| 03Aug | 0:30 | Attach hinges to brackets |

| 08Aug | 2:30 | Re-drill hinge arm pivot bearing holes and re-mount canopy; Cut canopy BH, removing entire center section |

| 10Aug | 1:00 | Move RH lift strut back a few inches to clear Fwd cover |

| (I have done a bunch of work, but have not yet updated this online log) | ||

| Nov | 0:30 | Moved entire project into a hangar at McKinney, Texas (TKI) |

| (I have done a bunch of work, but have not yet updated this online log | ||

E-mail

E-mail